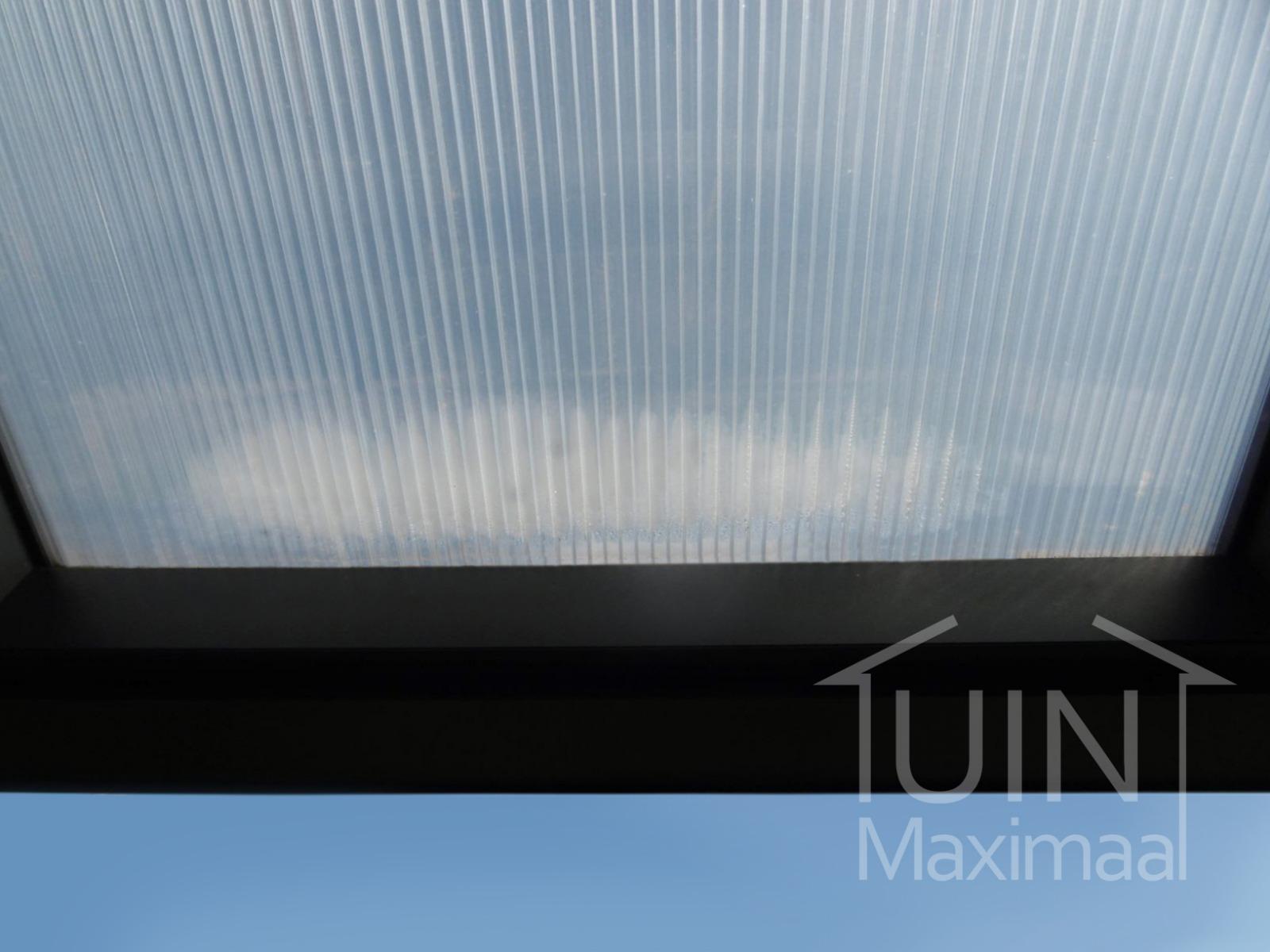

Condensation in polycarbonate panels is a natural phenomenon, which comes and goes. In practice, our customers hardly have any problems with excessive condensation in the polycarbonate panels, as long as they follow the installation instructions properly. After reading this blog, you will know more about condensation and what you can do to prevent it.

Why and when does condensation occur in polycarbonate panels?

Like almost all plastics, polycarbonate is waterproof, but not vapour proof. As a result, water vapour can always enter. If the humidity in the channels of the roof panels is high, condensation will occur when the panels are suddenly cooled down; after all, water precipitates on a cold surface. In practice, we only see this during weather changes, for example when the roof is cooled by rainfall. It is important that the condensation entering the polycarbonate roof panel also goes away and the condensation does not get stuck in the roof panels. Thanks to the AntiDust tape that is applied as standard, condensation disappears like snow in the sun every time.

The application of AntiDust tape causes condensation to disappear

Since you don’t want the condensation to stick around, our polycarbonate roof panels are fitted with AntiDust tape as standard. At the top of the roof panel is closed AntiDust tape, while the bottom contains perforated AntiDust tape. This allows condensation moisture to drain away and also allows air circulation in the roof panel. Are you shortening the length or width of a roof panel yourself during assembly? Then apply the appropriate AntiDust tape to the top and bottom, taking care not to damage the tape during assembly. You can order additional AntiDust tape with your order.

A glass roof as an alternative

Glass roof panels are a good alternative to polycarbonate if you suffer from condensation, as condensation simply cannot get between the tempered and laminated glass. Thus, unlike polycarbonate, glass is both waterproof and vapour proof. A glass roof also gives your Tuinmaximaal veranda a luxurious upgrade. Do you prefer to stick with polycarbonate? Because opal polycarbonate roof panels allow less light through than other types of polycarbonate panels, condensation is hardly noticeable.

What are the wrong solutions to combat condensation?

It seems like a good idea to leave the underside of the roof panels completely open, allowing accumulated water to flow out more easily. That may solve your moisture problem, but the open underside also leaves the door open to unwanted mould, algae and insects. The polycarbonate roof panels are therefore fitted with AntiDust tape and should be pressed into the nose profiles. Be sure not to press the panels past the raised edge inside the nose profile. This actually prevents air circulation in the panels. Finally, it is not advisable to use tape other than the recommended AntiDust tape. If you use a poor-quality tape, it may loosen or tear after a few years, allowing a large amount of water and dust to seep into the roof panels that cannot escape. In other words, prevention is better than cure. Right?

Want to know more about condensation? Then read this technical information from the manufacturer.